Built for every use case

Over 1,200 units deployed in just four years.

Every b:bot ships with embedded intelligence, remote monitoring, and audit-ready reporting. The machine is designed to accept eligible containers reliably, detect anomalies in real time, and prevent fraudulent activity.

All activity is logged and transmitted to operators, enabling traceability from deposit to material handover. Predictive maintenance and remote resolution maximise uptime.

Continuous monitoring and remote support keep machines operational, reduce downtime, and ensure fast resolution when issues occur.

Embedded AI continuously analyses machine data, predicts failures before they occur, and optimises performance across the network — ensuring maximum uptime and operational reliability without added complexity.

.jpg)

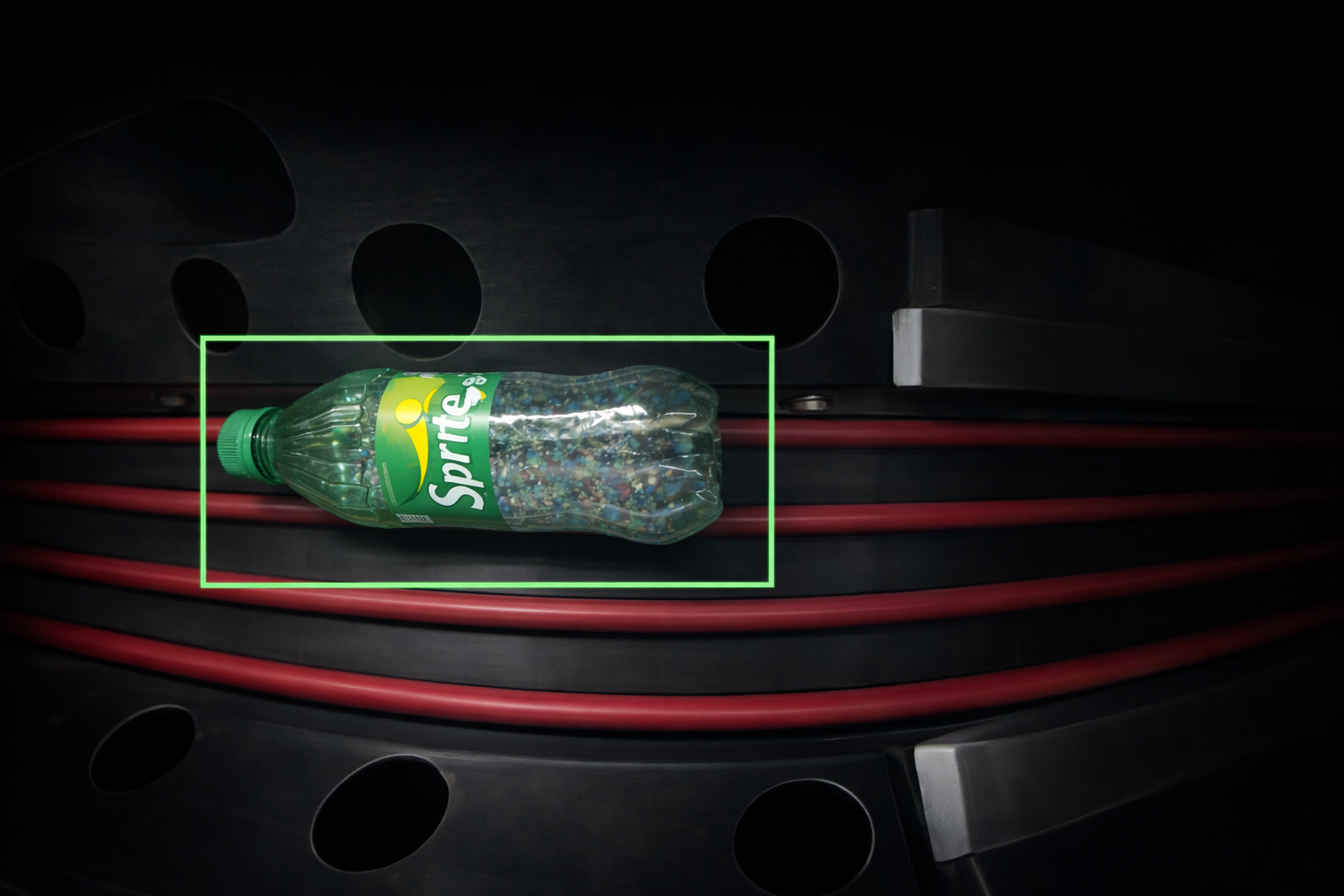

AI-powered image analysis detects suspicious behaviour and invalid containers in real time, protecting scheme revenues and ensuring compliance.

Every container is tracked and structured into actionable data, enabling accurate reporting, performance analysis, and operational optimisation.

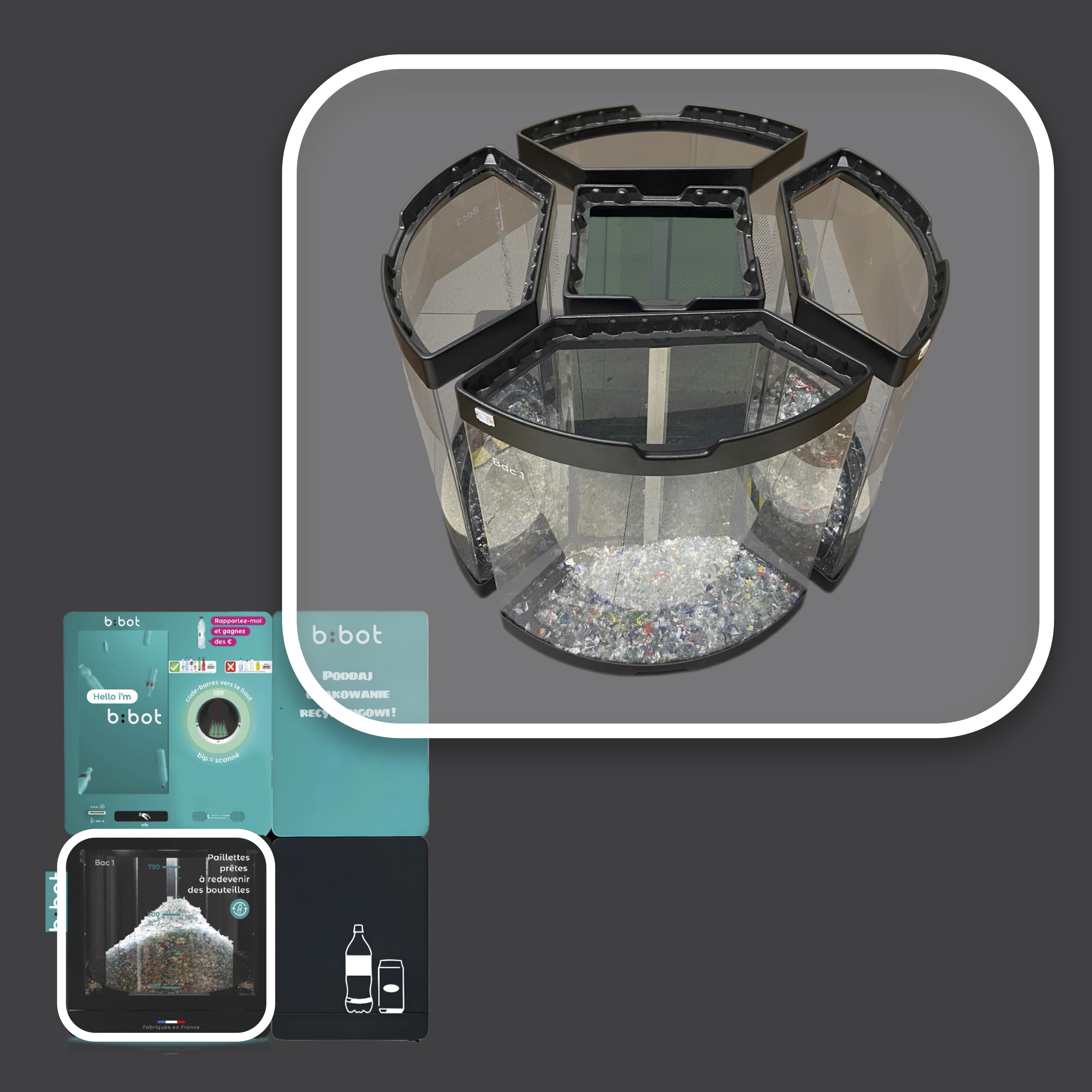

Multi-stream ready, b:bot accepts bottles, cans, and (where applicable) glass.

PET is where we improve collection economics; cans and glass follow standard DRS flows.

Product configurations

Retail environments

Glass in option

Outdoor deployment

Public spaces unsupervised

b:care

Uptime comes from knowing what breaks before it breaks. Our service model scales from routine store checks to remote diagnostics to field expertise.

b:care AI

Embedded AI adapts the machine's behavior to real conditions. It prevents failures by detecting early signals, then identifies and characterizes issues to accelerate resolution when support is needed.

b:care remote techs

Remote techs are the core of our maintenance model. They resolve up to 80% of incidents remotely because the machine is designed for it: key subsystems are connected, monitored, and remotely actionable.

b:care doctor

Field technicians step in when a physical intervention is required. They operate under defined SLA levels to restore service quickly and reliably.

Preventive care

Scheduled visits keep the machine consistently available: deep cleaning, full system checks, and shredder knife maintenance to sustain performance over time.

Customer inserts container into the acceptance port. System begins real-time capture and logging.

Computer vision reads barcode and validates container features against DRS records. Anti-fraud checks run in parallel.

Containers sorted by material type and colour class. Clear and coloured PET streams separated per market rules.

Material shredded, bagged, and tagged with unique ID. Audit trail and traceability data exported for DRS reporting.

Sorting

Containers are separated into two streams based on colour class. Clear stream captures clear and light blue/azure tones; coloured stream handles green, amber, and other hues.

Rules adapt to each market's requirements and recycler preferences.