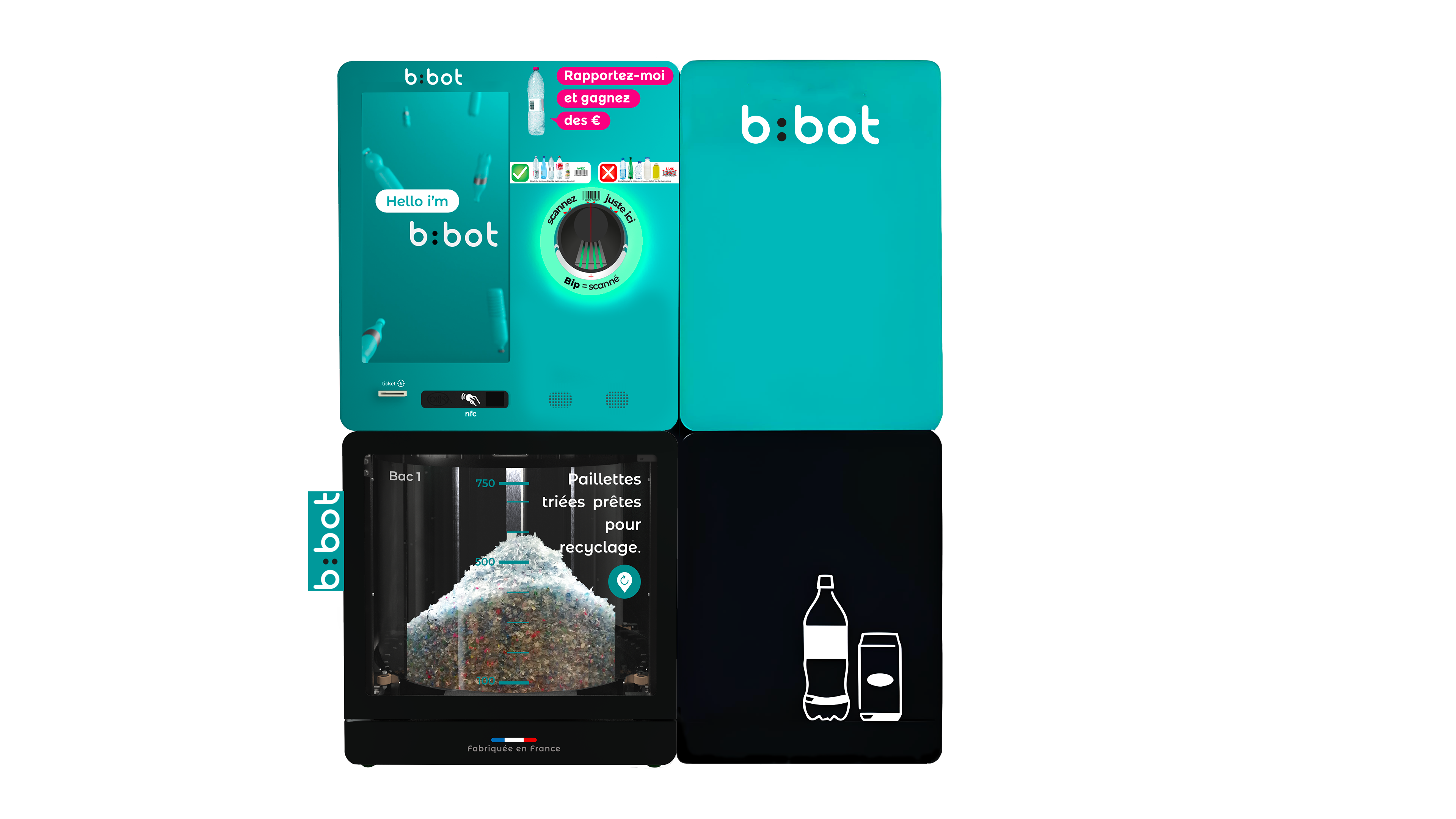

High-Density DRS

We collect bottles, cans and glass and we make logistics affordable by reinventing PET collection.

Density sets the cost baseline. Service, digital, traceability, and controls determine reliability, compliance, and scale.

Discover our technology and expertise that cuts complexity out of DRS logistics.

3500 bottles, 1500 cans, in 1.54 sqm

Weatherproof, all-season outdoor deployment

We have installed 1,200+ machines throughout France, including 150 in outdoor configurations. This deployment demonstrates that our shredding technology makes bottles and cans profitable to collect.

We have collected and recycled 500 million bottles through our shredding system in a bottle-to-bottle loop with Europe's leading recycling partner.

RVM leader in France, with 80% market share achieved in three years, working with France's leading retailers.

Each stakeholder gets a different outcome from the same machine.

Retail

More density means fewer emptyings, less handling, and less backroom space.

Operations

Transport is a major DRS cost driver. Higher density reduces trucks on the road from stores to hubs.

Recycling

PET upgraded at source with colour-separated streams and auditable traceability.

Brands

A density-first approach cuts the logistics cost of collection and makes DRS expansion financially sustainable.

Our mission

DRS is a logistics challenge. Taking back billions of containers is one of the most complex collection operations in the world. A major share of the cost comes from moving bulky, low-density packaging from thousands of collection points to a limited number of regional hubs. That's the problem we are solving.

.jpg)

The perfect fit for sites where space is scarce and logistics are expensive. b:bot reduces the volume of collected containers dramatically, so you don't lose tens of square meters to storage. You don't pay to transport air, especially from remote locations.

Expertise

Our teams know DRS from the inside. Ask about density, integration, or service.